ABOUT US

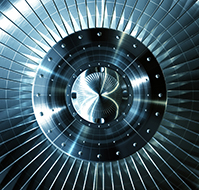

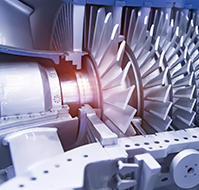

The engineering division was incorporated in 2008 in order to support companies to develop complex mechanic and technology engineering projects, in all their aspects, in the compressors & turbine for Oil&Gas, power and industrial application.

We offer specialized services and advanced solutions. We ensure efficient communication, timely delivery and reliable support to our clients.

Our emphasis is on state-of-the-art technology products and services, which facilitates the production in a cost-effective manner. This is accomplished through developing in-house capabilities and partnering with reputable high-end industrial providers of forgings, compressors and turbines.

Our familiarity and proximity to the major industrial hubs allows us to be in a favorable position to adapt and offer customized solutions to our regional clients.

OUR HISTORY

Initially, we concentrated our efforts on providing a service to Western European ME companies in two fields:

Metallurgy for Oil&Gas, turbines and compressors

Maintenance, revamping, servicing compressors and turbines (gas-fired and steam), supervising

Performances, reliability, flexibility are our targets in each project, from the initial design, to the operation, to the whole lifecycle.

SERVICES

-

Engineering studies: we offer to the Oil&Gas, Industrial Gases and Energy markets, equipment from the main European manufacturers and services thought standardized modular approach, in order to meet any customer’s need with the same top-class reliability, efficiency and flexibility.

-

Supervising overhauling compressors and turbines, steam and gas fired.

-

Regulatory and licensing requirements

-

Standardized components such as blades, journal and thrust bearings, seals, valves and couplings.

-

Diagnostics, performance evaluation, repairs, overhauls, and engineered upgrades of compressors and turbines, when possible on-site.

-

Integrated Procurement

-

Technical document development and review

-

Forging in alloys and superalloys for Oil&Gas Upstream/Downstream, Mining&Tunneling, ships, process equipment with deep knowledge of metallurgy for gas fired turbines, either disks and shafts:

-Technical evaluation of customer specifications, raw material suppliers.

-Wide press power range to reach the maximum quality of the grain.

-Definition of best parameters for complex processes VAR&ESR.

-Simulation of processes to foresee deformations during heat treatment, flow of material during forging operations.

-Failure analysis (critical aspects of complex projects.

-

Engineering and machining of equipment for steam turbines gas turbines.

-

Localization of documentation